Learning to Love

Surface Mount Technology (SMT)

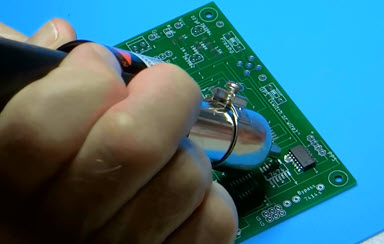

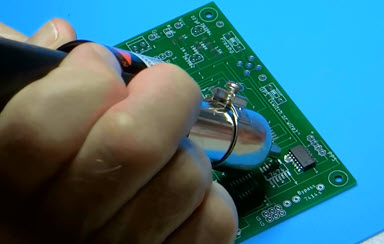

Lost in

translation: Somehow ‘soldering

practice’

becomes ‘welding practice’ in advertisements for certain small

electronics

kits

from China. I first practiced ‘welding’

surface mount devices (SMD) with two Gikfun kits:

flashing LEDs and infrared radar

(proximity sensing), each costing less than

$10. For the first kit I

used a fine-tipped

soldering iron and small diameter wire solder. The work was

challenging, especially the soldering of integrated circuit components,

but not

impossible. (The photos above are from product advertisements—not my

solder practice!) A circular pattern of flashing LEDs rewarded

successful

completion of the first kit (left in photo). In fairness, the kit makes good on its promise of soldering practice, although as a finished product it would not likely sustain long term interest.

More

hot

air: Before undertaking the second SMD practice exercise I

had acquired an Aoyue SMD Rework Station, along

with paste type solder, which is applied to the PCB (or stencil) by

squeezing from a syringe.

Through trial-and-error I zeroed-in on a temperature and airflow combination

that

melted solder without blowing the tiny components into the carpet, provided the

air flow nozzle was held at a suitable distance and angle with respect to

the target devices. For what it’s worth, the experimentally determined temperature was

225°

C. I cannot specify airflow rate meaningfully, because neither the Rework Station

nor its instruction manual identifies units for the

displayed air pressure

numbers—Air flow

was 15 something, units unknown.

More

hot

air: Before undertaking the second SMD practice exercise I

had acquired an Aoyue SMD Rework Station, along

with paste type solder, which is applied to the PCB (or stencil) by

squeezing from a syringe.

Through trial-and-error I zeroed-in on a temperature and airflow combination

that

melted solder without blowing the tiny components into the carpet, provided the

air flow nozzle was held at a suitable distance and angle with respect to

the target devices. For what it’s worth, the experimentally determined temperature was

225°

C. I cannot specify airflow rate meaningfully, because neither the Rework Station

nor its instruction manual identifies units for the

displayed air pressure

numbers—Air flow

was 15 something, units unknown.

Then

what? Without giving it thought

I had imagined that after the solder practice stage,

other

SMT kits would be available, not just for learning to work with surface mount

devices, but to make useful or interesting products on completion. I

had in mind an end result that would be richer

than flashing LEDs, not necessarily a big-screen TV, but somewhere between the extremes of solder practice kits

and manufactured electronics. Far as I can tell, no such

thing exists. Kits that include SMT components usually have those elements

pre-installed, with only through-hole components or socketed IC’s left

for

the builder to install. It appeared for a while as if the Rework Station would

gather dust,

which from time to time could be heated up and blown away (its self-cleaning feature). —But then

another

thought occurred..

Homebrew

SMT:

If kits of the type I imagined are uncommon, why not

convert one of my previous projects to SMT, or create an SMT project

from scratch. At this point I was unsure whether it would be

possible to purchase surface mount versions of popular op amps or

timers or

TTL, etc., in small quantities and at reasonable cost. What if such

components were only to be had in factory quantities? It would be crazy

to consider buying a thousand 555's in order to make one timer.

However, a quick Internet search confirmed that common SMDs can be

purchased in small

quantities from

companies like Mouser

or Digikey.

Since such components are small, and almost lighter than air, shipping

costs

are also reasonable.

Hidden

Advantage: From the amateur experimenter’s perspective, it

is important to keep the cost of projects as low as possible. Companies

that develop products for profit can afford to invest in advanced design software or sophisticated

hardware; whereas

amateurs or

students are generally obliged to pursue their interests

within stricter budgetary

constraints.

This thought led to an epiphany of sorts. You get more for

less with SMD than with the older more familiar

technology! The first such economy-of-scale poked through to

my awareness in relation to the circuit board design phase.

The non-commercial (free) version of Autodesk Eagle supports PCB

layouts of up

to 80 cm2, or nominally 80 mm × 100 mm. As a

guess, twice as much

circuitry can be packed onto this small design area using SMD than

using through-hole or socketed components.

This comparison is based

on circuits that are familiar to me—in other words,

amateur designs. LSI and multi-layer boards would boost component density to a much higher level.

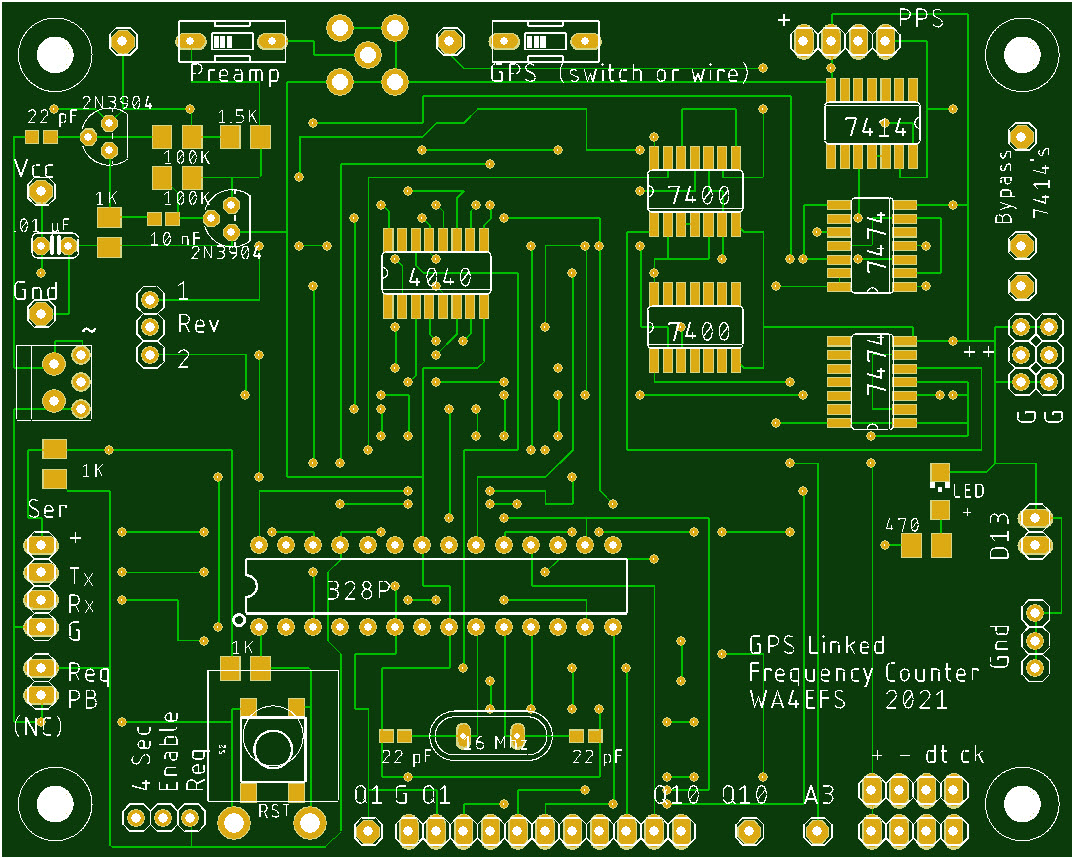

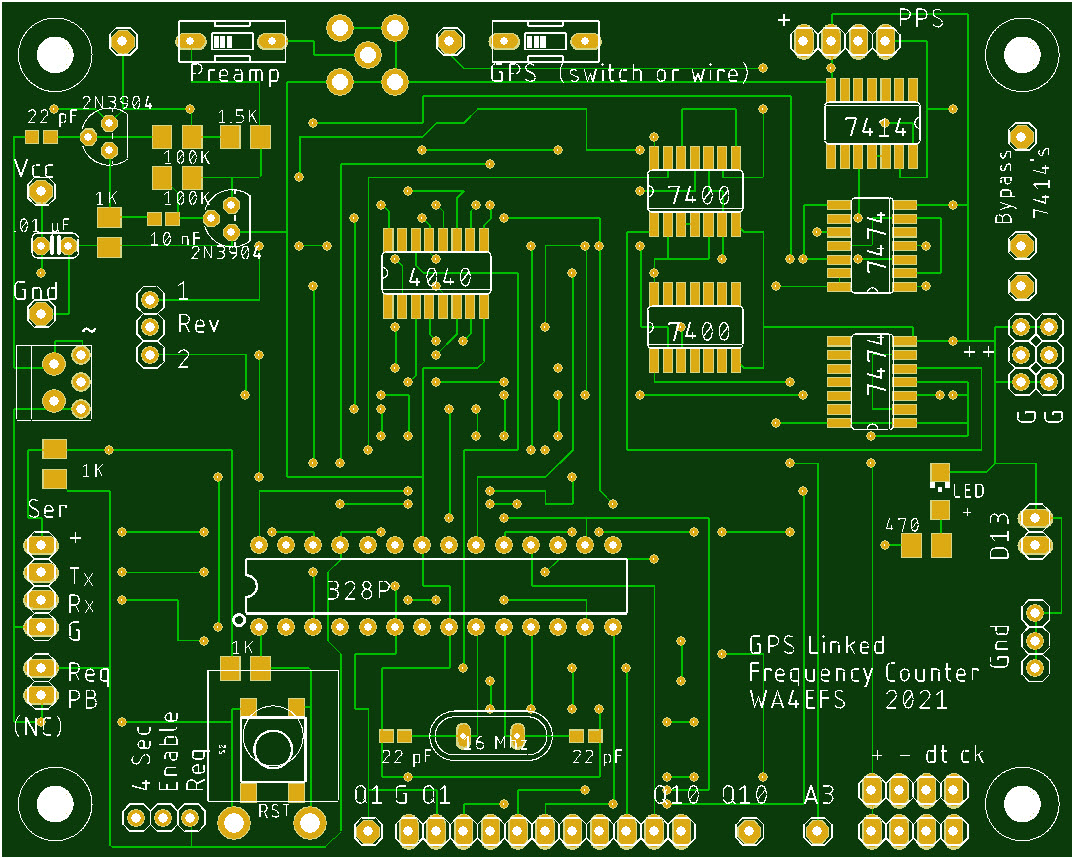

Picking

a

project: I didn’t immediately think of a novel idea for a

first homebrew SMT project. But one of my previous projects

included six DIP ICs (TTL). That same project also involved a small

number of resistors,

capacitors and LEDs. If redesigned for SMD, the project would be

significantly smaller, and should easily fit within an 8 cm ×

10 cm layout. Later I

came to realize that the close spacing of solder pads for

SMD IC’s, and the fact that they are all on the top PCB layer,

made

routing of connections more challenging. —Eagle

has an automatic routing feature, but I have not tried it. Manual

routing,

or at least my

manual routing is

very non-optimal. It relies on a great many vias. For this

prototype SMD project I placed each part as soon as it

was added to the schematic, and routed the traces (wires) that were

possible to route at that time. I did not draw the full schematic and place all

parts

before

starting to route connections. This one-part-at-a-time approach likely

contributed

to the large number of layer crossings (vias).

Boards:

I had ordered PCBs from JLCPCB before, and been entirely satisfied. CAM files were uploaded on Thursday and manufactured boards

(quantity 5) delivered the following Wednesday, China to Eastern US in 6 days,

including manufacture—Amazing! (This is not an advertisement.. I have

no connection to JLCPCB except as a customer.) Components that were not

on-hand (chiefly the TTL IC’s) were ordered concurrently from other

sources.

Solder

Practice Redux: It may be premature to claim having

improved my SMD soldering technique through practice with this first homebrew SMD project, but here goes.

After trying a few different approaches, one of which caused solder to pool

under the chip—definitely not good, I hit upon a method that

appeared to work

better than others. First the IC was positioned over the bare pads, and

in

the correct orientation for soldering. With the chip in position I

applied heat from a few centimeters height above one corner. This

warmed the board in the area to be soldered. Then I just touched the

heated part with solder paste—the heated board caused the paste to

liquefy and flow along the two or three pads/tabs to be soldered. Heat

was

again applied from above, this time for long enough to melt the solder

and cause it to flow onto the tabs, thus securing the IC at one corner.

Next I repeated the process on the opposite corner. By then

the board was generally hot enough to liquefy the paste, without the

necessity of applying additional heat. After the diagonally opposite

corner was secured I returned to the first side, and similarly soldered

the remaining pins, starting on the end away from the first

application. Finally I soldered the remaining pins. All connections were

shiny, with no excess or solder bridges. I used this method for all 6 ICs on

the third board belonging to this project. An inset toward the

end of the video demo (see link below) illustrates this process. It was by

far the

cleanest of several tries. No resoldering was needed.

I should clarify that on a previous board I had

applied cold paste in greater quantity, and afterward had to desolder

several ICs, clean the board, and

resolder them. Another practice board was fine electrically, but not as

clean as the

one soldered using the technique outlined in the preceding paragraph.

Of course, proper equipment, including a stencil frame and oven would

surely produce the same or a better result. However, when a hot air

reflow station is the only tool available, it remains possible to

solder SO-14 or SO-16 footprint ICs very cleanly—perhaps, as in my

case, by substituting patience for experience.

Acknowledgements:

Although the GPS

Frequency Counter project in its original

form has been described on a separate page, I want to reacknowledge key

sources that contributed to the concept. First, the

idea of

using a GPS to define the counting interval came from the QRP

Labs QCX transceiver kit, and subsequent correspondence with

its designer Hans Summers G0UPL. The preamplifier circuit (upper left

corner of PCB) came from the Four

State QRP Group Frequency Mite kit, designed by Dave Benson

K1SWL. I have included the revised schematic above (i.e., the SMD

version of

the project). For more detail please refer to the original write-up (non SMD

version). Finally the microcontroller sketch for the project described

on this page may be found here.

Demo video: Learning to

Love SMT

Project descriptions on this page are intended for entertainment only.

The author makes no claim as to the accuracy or completeness of the

information presented. In no event will the author be liable for any

damages, lost effort, inability to carry out a similar project, or to

reproduce a claimed result, or anything else relating to a decision to

use the information on this page.

More

hot

air: Before undertaking the second SMD practice exercise I

had acquired an Aoyue SMD Rework Station, along

with paste type solder, which is applied to the PCB (or stencil) by

squeezing from a syringe.

Through trial-and-error I zeroed-in on a temperature and airflow combination

that

melted solder without blowing the tiny components into the carpet, provided the

air flow nozzle was held at a suitable distance and angle with respect to

the target devices. For what it’s worth, the experimentally determined temperature was

225°

C. I cannot specify airflow rate meaningfully, because neither the Rework Station

nor its instruction manual identifies units for the

displayed air pressure

numbers—Air flow

was 15 something, units unknown.

More

hot

air: Before undertaking the second SMD practice exercise I

had acquired an Aoyue SMD Rework Station, along

with paste type solder, which is applied to the PCB (or stencil) by

squeezing from a syringe.

Through trial-and-error I zeroed-in on a temperature and airflow combination

that

melted solder without blowing the tiny components into the carpet, provided the

air flow nozzle was held at a suitable distance and angle with respect to

the target devices. For what it’s worth, the experimentally determined temperature was

225°

C. I cannot specify airflow rate meaningfully, because neither the Rework Station

nor its instruction manual identifies units for the

displayed air pressure

numbers—Air flow

was 15 something, units unknown.