μBITx

tuned to WWV at 10 MHz

Calibrating

the μBITx (version 5.1) should have

been an easy chore or,

according to some sources,

no chore at all. The

unit is factory aligned, they say. Perhaps so, but WWV does not

transmit at 9,998 KHz, as my μBITx Liquid Crystal Display was

indicating.

Although there is no operating manual

for the unit, a variety of Internet sources describe straightforward

procedures for calibration. Unfortunately, it is not always

clear which sets of directions apply to which firmware versions.

Different

versions

appear to use different calibration methods.

First attempts: Relying

on relevant Internet sources, along with the unit’s Settings menu

prompts, I

attempted to correct the frequency error in my μBITx,

but made no

discernable progress. To

be clear,

I do not fault the manufacturer for this failure. I accept responsibility for not

performing the calibration procedure properly.

Strange things

happened. For example, the unit appeared to key down spontaneously

(or PTT on) at the 10 MHz calibration frequency. This unnerved me. And in

any case I

was at a loss as

to how to tune with the receiver muted. Later

I

asked a fellow μBITx owner if he had experienced any problem

when calibrating his unit. He had not. I am envious of

those who do the right

thing instinctively

when directions are

sparse or menu prompts unclear.

The hard way:

Perhaps I am naturally inclined to hit upon the

hard way of accomplishing simple things. After hours of

frustration spread over two days I thought to examine the μBITx

sources

to see if they would shed light on the proper or intended calibration

procedure. I was not

sure that the same version numbered sources on github were identical to the

factory-installed firmware, but supposed

that they must be at least similar.

The hard way:

Perhaps I am naturally inclined to hit upon the

hard way of accomplishing simple things. After hours of

frustration spread over two days I thought to examine the μBITx

sources

to see if they would shed light on the proper or intended calibration

procedure. I was not

sure that the same version numbered sources on github were identical to the

factory-installed firmware, but supposed

that they must be at least similar.

From the source code it was clear that

calibrating the unit stores a signed

32-bit correction in EEPROM. This observation suggested the idea of

reading out

the μBITx EEPROM,

and examining the calibration number stored there. First

though,

it seemed prudent to back up the factory

Nano, in case some mishap were to

render it inoperable. This was probably

unnecessary, as I had previously tested a replacement Nano built from

the compiled github

sources. The

μBITx appeared to work

with this Nano the same as with factory firmware.

But from what is popularly called an ‘abundance of caution’

I decided to duplicate the factory

Nano before fiddling with

it.

case some mishap were to

render it inoperable. This was probably

unnecessary, as I had previously tested a replacement Nano built from

the compiled github

sources. The

μBITx appeared to work

with this Nano the same as with factory firmware.

But from what is popularly called an ‘abundance of caution’

I decided to duplicate the factory

Nano before fiddling with

it.

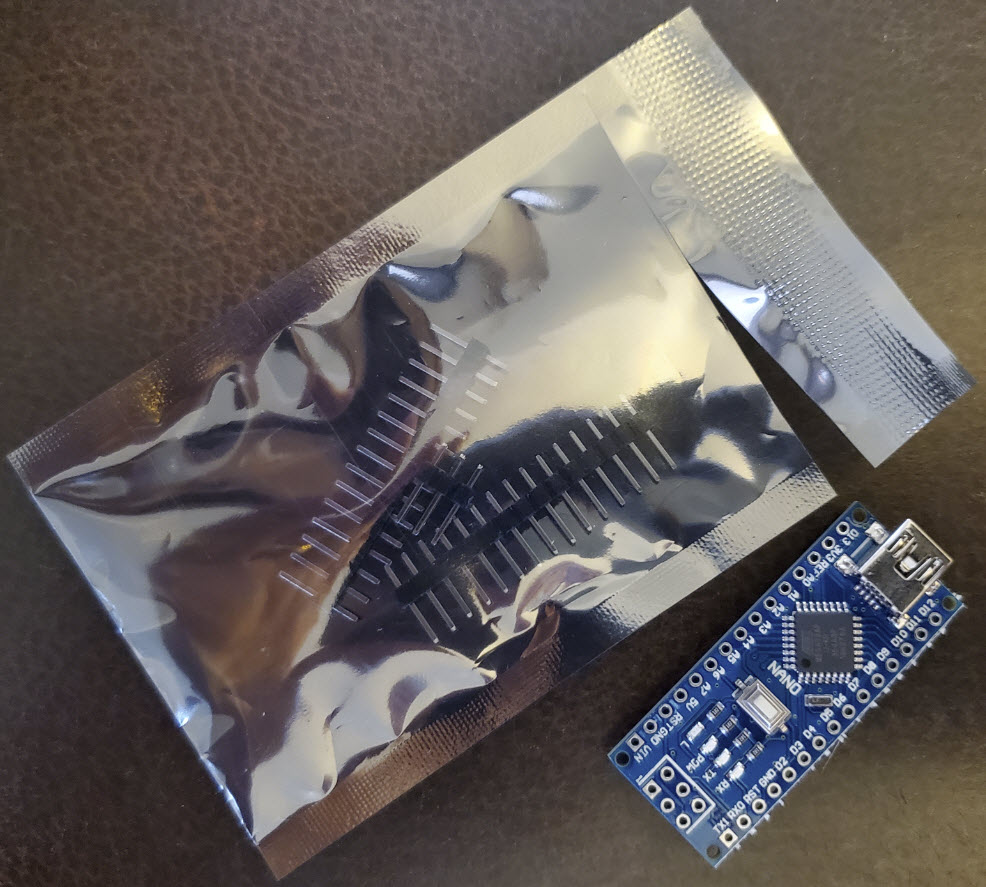

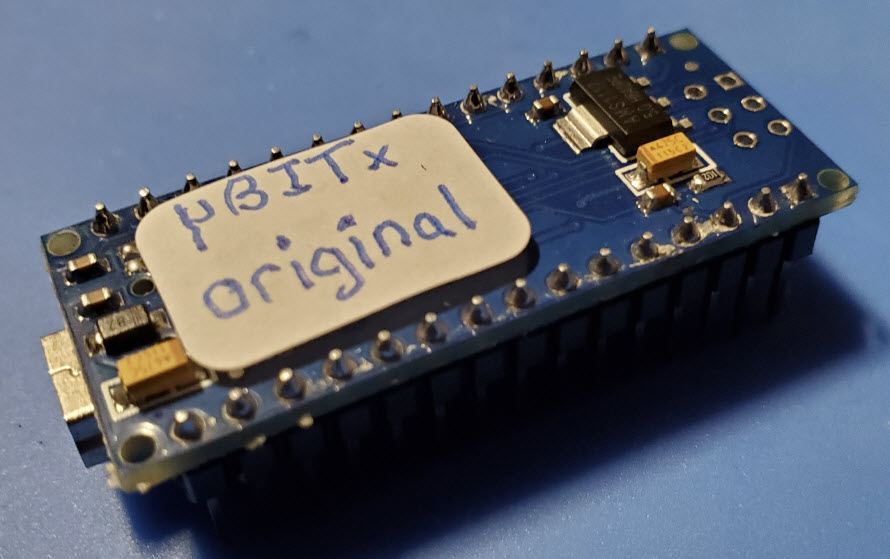

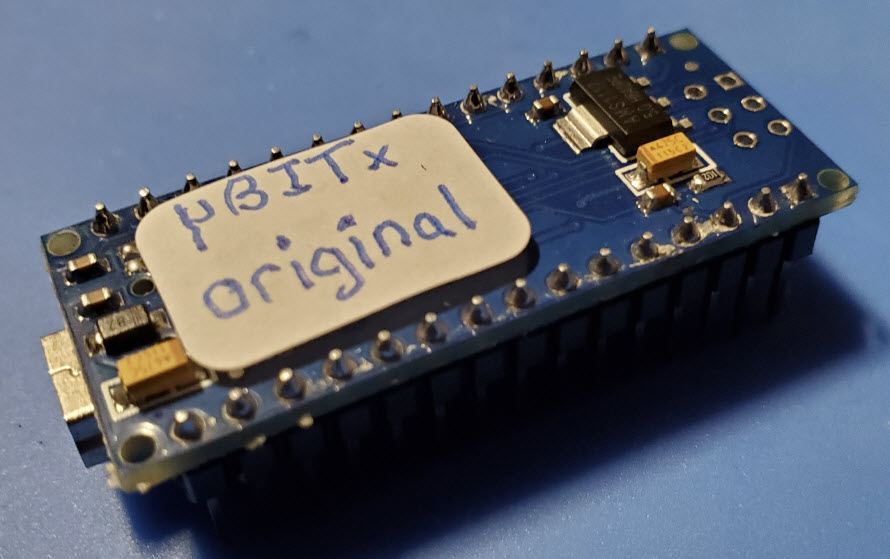

Note: μBITx

Nano pin headers are installed on the component side. Thus the USB

connector and reset button are on the inside of the Raduino assembly

(toward the Si5351 and LCD). If duplicating, be sure to solder pin

headers on the same side as they are on the

original

μBITx

Nano. See photo above right.

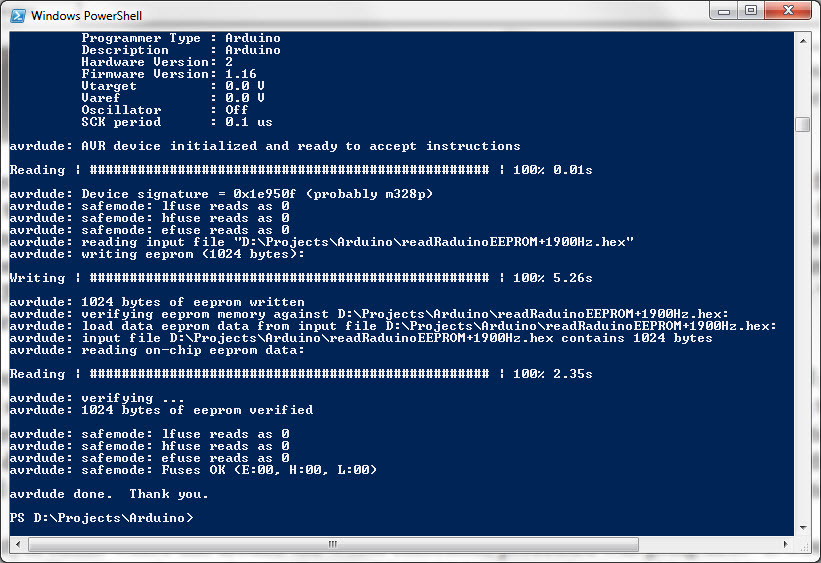

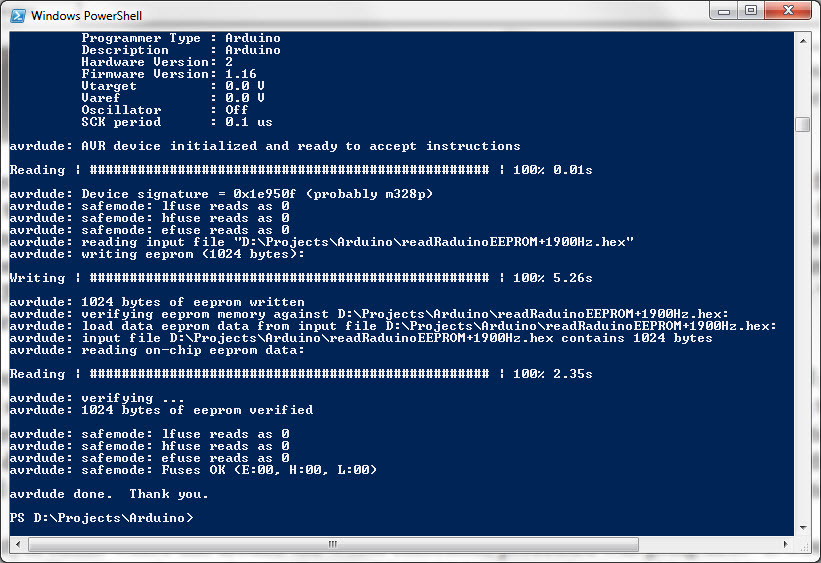

The program avrdude.exe is part of the

Arduino IDE distribution and can be used to read or write EEPROM or

flash

memory

to or from a host computer file in Intel

HEX format (or other formats). A tutorial was helpful to

understand

the range of options supported by this very flexible utility.

After experimenting with program parameters I created four small batch

scripts to

wrap calls, mainly because the paths for the configuration

file and

input/output files were long and tedious to type or copy/paste. These

scripts correspond to avrdude parameter values specifying to 1. read

EEPROM,

2. read Flash, 3. write EEPROM, and 4. write Flash. Only

the virtual serial port for the Nano and the input or output

file name vary with different usages.

Example batch script (Read

EEPROM to iHEX file)

After test duplicating and verifying an

unrelated

Nano—one that had been used in a previous project, I copied EEPROM and

flash

from the μBITx factory

Nano to Intel HEX format files. However, on attempting to restore

flash

contents from the stored hex file to a different Nano, avrdude verify

failed.

Furthermore, it was no longer possible to upload any sketch to the

target

Nano from the Arduino IDE without encountering the same

verify failure.

‘Unbricking’

(restoring the bootloader)

‘Unbricking’

(restoring the bootloader)

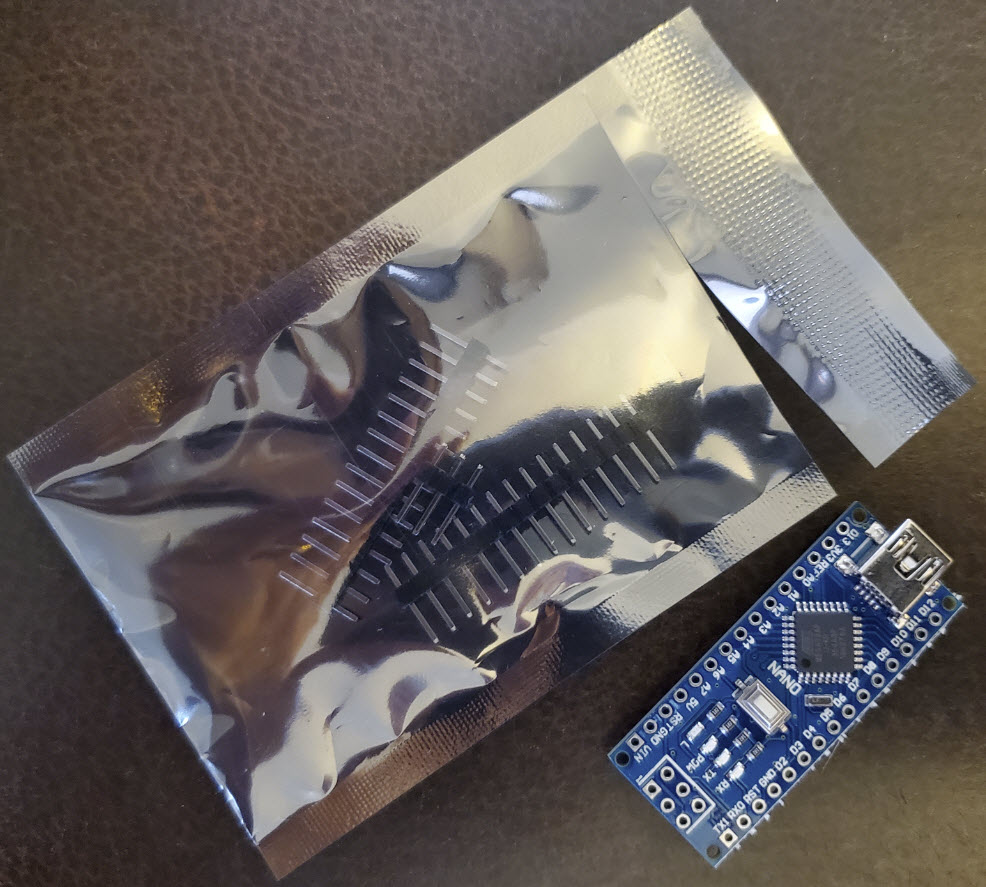

Two bricked Nanos: A

common impediment to efficient problem solving is perseveration. My

first

thought was that the Nano itself was defective, which led to repeating

the flash-copy sequence with another Nano—the last on hand. However, it

soon

became

apparent that the problem related to the

copied bootloader, which was different than the one

the configuration

was expecting. That led to yet another side study, how

to restore

the

Nano bootloader. For this I used the

ArduinoISP sketch (found in the

IDE examples). Carrying

out this well-documented exercise—see

photo above—‘unbricked’

the two Nanos,

but then the realization occurred that simply not overwriting the

bootloader would have prevented the problem in the first place. But

where in flash memory is the Nano bootloader?

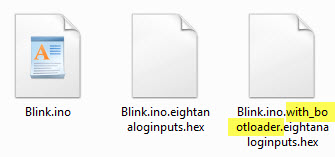

Sketch folder contents

The following trick revealed

the

answer. 1. Load the blink sketch (or any short sketch). 2. Select

‘Export

compiled Binary’ from the IDE Sketch menu. 3. From the same menu choose

the ‘Show Sketch Folder’ option. The folder contents include two

hex files (illustration

above), one of which has

‘with_bootloader’ as part of the file name.

4. Compare the contents of these two files—I used WinMerge

for a side-by-side view. This comparison showed that the Nano’s

bootloader starts at address 0x7E00. It may be possible to

specify an address range to avrdude, but instead I deleted the

bootloader code section from the μBITx flash

hex file before writing

the modified file to a test Nano. Upon

doing this, both write and verify succeeded. EEPROM also loaded to the

test Nano without incident. The final hurdle was to verify the ‘factory

backup’

Nano in the μBITx

itself.

As with the earlier test using compiled sources, this copy appeared to

work the same as the original.

μBITx

EEPROM contents:

Although these paragraphs present an approximate chronology, in

fact I

had

already examined μBITx EEPROM

contents before resolving the flash duplication issue. To do this I

wrote a simple

Arduino

sketch to display EEPROM values corresponding to the same

variables and datatypes

stored by the μBITx

firmware. This one-off

sketch duplicated μBITx

EEPROM address definitions and global variable declarations, and

displayed formatted values via the Serial monitor. It was reassuring

to observe that the Morse keyer speed (stored dot duration) agreed with

the known

value for this setting. However, the Si5353 calibration number was 0.

This was unexpected. Had it always been such, or had I inadvertently

caused 0 to be

stored there in an aborted calibration attempt? Almost surely it was

the latter, but there was no way

to know.

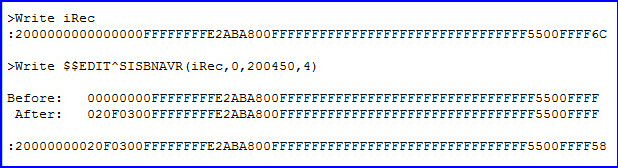

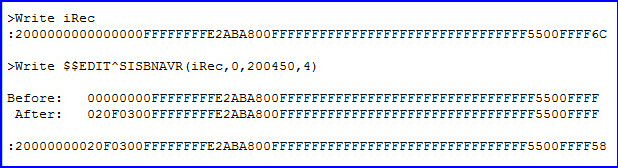

avrdude.exe read/write/verify

By this point it was clear

where this circuitous calibration procedure would be going next. It

would have been possible to construct another simple Arduino sketch to

store (put) trial

calibration values to

EEPROM, whence they

could be read by avrdude and uploaded to the μBITx

Nano, a sort of mirror sketch to the one for displaying μBITx

settings. However, I

thought it would be good to become familiar with

the Intel HEX file format for possible future use,

and maybe to skip a step or two in the potentially repetitious testing

cycle. To that end I created a function to accept an Intel HEX data

record as

input, along with a decimal address, decimal replacement value, and

number of bytes corresponding to the changed value’s datatype, then

generate

a replacement HEX record, and recompute the checksum, etc. For

expediency, I programmed this part in MUMPS, not c++, so there would be

little point

in posting the code here. It is not a difficult exercise in any case.

First convert each test replacement value to hex and reverse the byte

order (left-to-right

is least significant to most significant). The

checksum

algorithm is described in the previously referenced Wikipedia page, and

is also

easy to compute. Finally, slap in the edited hex using a text editor (I

used Notepad++),

and upload with avrdude.

(μBITx variables

of interest do not wrap the 32 byte data records.)

Replacement iHEX record for

decimal test value

From reading or rather skimming the

μBITx

source code I deduced that the value 875 corresponds to a delta of 10

Hz, but wasn’t sure of the sign. Really I was not sure of anything, and

therefore

decided to start with a small number for the EEPROM stored calibration.

This first test value confirmed

the guess that if the

true frequency

is greater than the LCD frequency the sign is positive. After this

edit, the displayed

frequency was about 500

Hz closer to the true

frequency. So I repeated

the procedure twice more until

WWV appeared at 10 MHz on the LCD. (Prior

to each frequency adjustment the BFO was reset to the same value.)

At

this point I switched to a different kind of test. Tuning to a lower

sideband station near 7.150 MHz I observed that voice quality was

clearest (most natural) when the

frequency display was 50 Hz above the even KHz transmit frequency

(verified on a separate receiver). A final tweak of the calibration

number made 40-meter LSB voice stations sound clearest on their

transmit frequencies.

I also tuned in FT8 activity at 7.074 MHz USB.

It feels awkward to

tune an AM

station with a receiver that does not have AM mode. However,

WWV tuned at 10 MHz on the display within

the precision of observation. Voice

announcements were

equally clear on both sidebands at the same display frequency. The

‘final’

calibration number for my μBITx

(Si5351) was +181,000 decimal (2068 Hz), but of course that particular value is meaningless for

any other μBITx.

Not recommended:

As a means of calibration, the EEPROM editing procedure described in

the preceding paragraphs was born of

desperation. Obviously it lacks the simplicity of direct methods, or

the precision of calibrating with instruments, although probably

good

enough for ordinary operation. I had recently recalibrated a different

QRP rig, the CW-only single-band QCX from QRP Labs. That was a piece of

cake. Just hook up the GPS and count cycles between time ticks. Wow! Possibly that

too-easy experience contributed to my impatience with the μBITx,

or my failure to follow the steps for performing calibration properly

via the Setup menu options. I do not recommend calibrating in the

roundabout

way described here. On the other hand these studies were instructive.

They highlighted features of

the microcontroller and programming utilities that may prove useful in

other contexts.

Demo video: ubitx_frequency_calibration.mp4

Project descriptions

on this page are intended for entertainment only.

The author makes no claim as to the accuracy or completeness of the

information presented. In no event will the author be liable for any

damages, lost effort, inability to carry out a similar project, or

to reproduce a claimed result, or anything else relating to a decision

to

use the information on this page.

The hard way:

Perhaps I am naturally inclined to hit upon the

hard way of accomplishing simple things. After hours of

frustration spread over two days I thought to examine the μBITx

sources

to see if they would shed light on the proper or intended calibration

procedure. I was not

sure that the same version numbered sources on github were identical to the

factory-installed firmware, but supposed

that they must be at least similar.

The hard way:

Perhaps I am naturally inclined to hit upon the

hard way of accomplishing simple things. After hours of

frustration spread over two days I thought to examine the μBITx

sources

to see if they would shed light on the proper or intended calibration

procedure. I was not

sure that the same version numbered sources on github were identical to the

factory-installed firmware, but supposed

that they must be at least similar. case some mishap were to

render it inoperable. This was probably

unnecessary, as I had previously tested a replacement Nano built from

the compiled github

sources. The

μBITx appeared to work

with this Nano the same as with factory firmware.

But from what is popularly called an ‘abundance of caution’

I decided to duplicate the factory

Nano before fiddling with

it.

case some mishap were to

render it inoperable. This was probably

unnecessary, as I had previously tested a replacement Nano built from

the compiled github

sources. The

μBITx appeared to work

with this Nano the same as with factory firmware.

But from what is popularly called an ‘abundance of caution’

I decided to duplicate the factory

Nano before fiddling with

it.