AD9834 DDS

(Part 1):

I have separately described a project based on the Analog Devices

AD9850 chip (see AD7C

VFO

write-up). The following paragraphs are about how to figure out

and test another DDS

chip, the AD9834.

The

board shown on the right in the illustration above was purchased on

eBay. It is similar to this one, with three SMA jacks

labeled Sine1, Sine2, and Square. The AD9834 chip is well-documented in

the Analog

Devices datasheet and related application note. For example,

AN-1070 by Liam Riordan explains how to compute and load a

frequency into one of the chip’s frequency select registers. However,

there

seem to be few completely documented applications for this chip, and

none that I could find referencing the specific evaluation board I

purchased. The

small mail packet from China included only the board—no schematic or

other documentation.

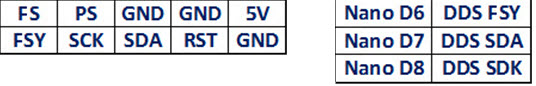

The PCB connector labels (left) were a mixture of familiar and

unfamiliar

terms. Power connections and SDA / SCK were familiar,

and

The PCB connector labels (left) were a mixture of familiar and

unfamiliar

terms. Power connections and SDA / SCK were familiar,

and RST for ‘reset’

was meaningful, although I didn’t

know what to do with it. I still do not know what

the abbreviations PS and PSY stand for, although I was able to deduce

what to do with one of them. By tracing AD9834 pin 15 on the circuit

board, I found that the chip’s

FSYNC (datasheet page 9) goes to the header pin labeled PSY.

RST for ‘reset’

was meaningful, although I didn’t

know what to do with it. I still do not know what

the abbreviations PS and PSY stand for, although I was able to deduce

what to do with one of them. By tracing AD9834 pin 15 on the circuit

board, I found that the chip’s

FSYNC (datasheet page 9) goes to the header pin labeled PSY.

Correction:

A correspondent informed me that what I had read as ‘PSY’

was actually ‘’FSY’.

Mr. Glen Wilson very kindly sent the following corrected figures, and

explained the abbreviations that had puzzled me.

According

to Mr. Wilson, “The Fselect pin is used for FSK modulation. Low selects

one of the pre-programmed frequencies as stored by the Arduino program;

a high will send the other. Pselect is similar [but] selects different

phases for PSK modulation.” This explanation eliminates the confusion I

expressed in the preceding paragraph. Unfortunately the block diagrams

in the second part of this article (below) also include the erroneous

‘PSY’ annotation.

Many hours went down the tubes in a variety of failed attempts to

communicate with the AD9834 before I came across a tremendously useful

test sketch authored by Alexander C. Frank, and originally written for

the AD9833. The sketch may be found near the bottom of this page.

Many hours went down the tubes in a variety of failed attempts to

communicate with the AD9834 before I came across a tremendously useful

test sketch authored by Alexander C. Frank, and originally written for

the AD9833. The sketch may be found near the bottom of this page.

The PCB master clock frequency is

stamped on the crystal (photo left). To adjust

Mr. Frank’s program for

this clock frequency is a

trivial one-line edit. That is in fact the only

thing I changed in the sketch. The wiring is also simple, once it was

clear which pin

was FSYNC (table above). One other very minor clarification...

Mr. Frank’s

Arduino sketch uses serial COM for user input. When entering a

test frequency and waveform type via the serial device use ASCII

10 (newline) as the

command terminating character.

Generated sine and triangular waves are

output via the Sine1 jack, while square waves are output via the

top-mounted jack. The oscilloscope probe was capacitively coupled for

the test sine wave shown above (7.036 MHz), but directly coupled for

the other two examples (100 KHz square wave and 5 KHz

triangular). In other words, while the Square wave output is centered

on 0 volts, the triangle (via Sine1) is centered on half its P-P

voltage, and the sine output would be also if the probe were not

capacitively coupled.

The drop-off in output with increasing

frequency is greater than I recall seeing from the AD9850. Above 30 MHz

the signal is messy, and hardly measurable. Of course, these readings

reflect breadboard wiring, with a 2200 ohm load resistor. A better

result might be expected from an improved test setup.

AD9834

DDS Demo: RTTY.mp4

AD9834 DDS and FSK (Part 2):

The above demo

video introduces something that was not discussed in the accompanying

write-up, viz

an Arduino application called TinyFSK written

by Andrew Flowers K0SM. Two Arduino Nanos were used for the demo, one

running TinyFSK and the other to control the AD9834. Outputs of the FSK

Arduino connect to inputs of the AD9834 controller, as shown in the

diagram below.

It occurred to me

that the two programs (sketches)

could be combined and that one Nano would suffice for both FSK and

controlling the DDS. Blending the two programs turned out to be easier

than expected. Starting with TinyFSK, I imported just enough AD9834

control code to generate a sine wave for a specified frequency, and

then inserted calls to update the frequency at

each place where TinyFSK writes to a DIO pin.

It was unclear at first how to turn transmit OFF, but specifying 0 Hz

for the frequency worked! There

was no memory crunch, so no need to remove TinyFSK’s

DIO writes (FSK_DDS.ino).

For

the audio FSK

demonstration in the first part of the preceding video, output from the

DDS was fed to the computer sound card line-in jack. In the second part

of the video, the AD9834 was configured to generate RF at 7.1 MHz (+

FSK offsets). According to my calculation, output power was less than 1

milliwatt. However for this demo, transmit and receive antennas were

only about 50 feet apart.

The video does not

include an intermediate test in which an RTL dongle and SDR were used

to receive RF from the DDS. For this exercise, the receive antenna was

a length of wire hanging over the stairwell, no more than 10 feet from

the transmit antenna!

In the screen capture image, Termite

(lower left)

keys the FSK Arduino. On the right SDR# receives the 7.1 MHz signal.

Finally, MMTTY (upper left) decodes the

SDR’s audio output.

Observe that decoding lags a couple of characters behind the sender.

All this started as a small-scale

exploration of the

AD9834. I never intended to get into FSK, and certainly not to go

further than encoding and decoding a signal, but sometimes it

is hard to stop, even when one’s

better judgement screams ‘enough already’. Thus,

in a roundabout way I became curious about how to amplify DDS-generated

RF output. Although

the Arduino connection diagrams (above) include the legend ‘to

amplifier’, none of the demos involved an amplifier. At some point I

wondered whether DDS output could be boosted sufficiently to drive the Pacific

Antenna 10-watt linear amplifier.

That would mean increasing the output to a few hundred milliwatts at

least. Unfortunately I

know almost nothing about RF amplifiers.

An obvious next step was to examine a few example low-power RF

circuits, such as the Pixie or the One-Watter (both described near the

top of this page). I also found a couple of circuits on the Internet

covering the power range of crystal oscillator to fractional-watt

output. Although

differing in detail, these reference circuits exhibit common features,

which I attempted to understand and duplicate.

A little bit of experimentation

with different components or values and two

stages of amplification eventually

led to a potentially exploitable result. RF output measured

about

3 volts P-P across a 50 ohm resistor. So far so good, although the

second stage transistor got very hot. To

address

the heat problem, I fabricated a heat sink from aluminum bar stock and

a ring terminal. (The idea of using a ring terminal for bonding the

heatsink to the TO-92 came from the Pacific Antenna QRP amplifier

project, where a ring terminal is used to draw heat from a diode.)

Loose wires are the bane of breadboard construction—the greater the

component count the more likely it is that something will work loose.

So it was with the amplifier. Sometimes it worked and sometimes not, so

I reconstructed the circuit on a generic PCB, more or less the same as

it was, adding a PTT relay and some test points.

Sometime later a transistor lead broke due to the heatsink bending

whenever the board was turned over, or from accidentally setting my

coffee cup on it. When this happened, I unsoldered the transistors and

installed 3-hole headers so that the transistors could be easily

replaced or exchanged for different values, etc. But that was later.

First I hooked the PCB preamplifier to the 10-watt linear.

Preamplifier output was not up to the linear’s minimum spec., but

“nothing ventured nothing gained.”

Sometime later a transistor lead broke due to the heatsink bending

whenever the board was turned over, or from accidentally setting my

coffee cup on it. When this happened, I unsoldered the transistors and

installed 3-hole headers so that the transistors could be easily

replaced or exchanged for different values, etc. But that was later.

First I hooked the PCB preamplifier to the 10-watt linear.

Preamplifier output was not up to the linear’s minimum spec., but

“nothing ventured nothing gained.”

The entire test setup consisted of the DDS and control Arduino (still

on breadboard), the amplifier PCB, the linear, an MFJ-971 QRP tuner

(for the meter), and a 10 watt resistive dummy load (not the wire wound

resistor shown in the breadboard photo). The linear has a

transmit relay keyed by RF and there was barely enough RF to

key

it. In fact, transmit keying was not consistent. Sometimes it keyed and

sometimes it didn’t.

When fortune smiled, the tuner meter

moved. Yes I know it is ugly, but however

that may be, in my world when the meter moves the experiment must count

as a success! Of course,

something is not right. How

could a resistive load reflect a third of the power? A possible clue is

that RF signal quality degrades significantly when the PCB

amplifier is connected to the linear (with the latter powered on). To

investigate further I have ordered a few bigger transistors, with a

view to adding a third stage to the preamplifier.

(To be continued, maybe...)

Footnote: One

of the routine ‘smoke tests’ carried out during construction produced

actual smoke. This does not happen often and was therefore especially

gratifying, although an acrid smell lingered for several hours

afterward.

Project descriptions on this page are intended for entertainment only.

The author makes no claim as to the accuracy or completeness of the

information presented. In no event will the author be liable for any

damages, lost effort, inability to carry out a similar project, or to

reproduce a claimed result, or anything else relating to a decision to

use the information on this page.

The PCB connector labels (left) were a mixture of familiar and

unfamiliar

terms. Power connections and SDA / SCK were familiar,

and

The PCB connector labels (left) were a mixture of familiar and

unfamiliar

terms. Power connections and SDA / SCK were familiar,

and RST for ‘reset’

was meaningful, although I didn’t

know what to do with it. I still do not know what

the abbreviations PS and PSY stand for, although I was able to deduce

what to do with one of them. By tracing AD9834 pin 15 on the circuit

board, I found that the chip’s

FSYNC (datasheet page 9) goes to the header pin labeled PSY.

RST for ‘reset’

was meaningful, although I didn’t

know what to do with it. I still do not know what

the abbreviations PS and PSY stand for, although I was able to deduce

what to do with one of them. By tracing AD9834 pin 15 on the circuit

board, I found that the chip’s

FSYNC (datasheet page 9) goes to the header pin labeled PSY.

Many hours went down the tubes in a variety of failed attempts to

communicate with the AD9834 before I came across a tremendously useful

test sketch authored by Alexander C. Frank, and originally written for

the AD9833. The sketch may be found near the bottom of this page.

Many hours went down the tubes in a variety of failed attempts to

communicate with the AD9834 before I came across a tremendously useful

test sketch authored by Alexander C. Frank, and originally written for

the AD9833. The sketch may be found near the bottom of this page.

Sometime later a transistor lead broke due to the heatsink bending

whenever the board was turned over, or from accidentally setting my

coffee cup on it. When this happened, I unsoldered the transistors and

installed 3-hole headers so that the transistors could be easily

replaced or exchanged for different values, etc. But that was later.

First I hooked the PCB preamplifier to the 10-watt linear.

Preamplifier output was not up to the linear’s minimum spec., but

“nothing ventured nothing gained.”

Sometime later a transistor lead broke due to the heatsink bending

whenever the board was turned over, or from accidentally setting my

coffee cup on it. When this happened, I unsoldered the transistors and

installed 3-hole headers so that the transistors could be easily

replaced or exchanged for different values, etc. But that was later.

First I hooked the PCB preamplifier to the 10-watt linear.

Preamplifier output was not up to the linear’s minimum spec., but

“nothing ventured nothing gained.”