I

made no effort to optimize the display modifications. It is possible

that the compiler warning might be avoided by removing redundancies,

replacing strings with small character arrays, and making other

efficiencies. On the other hand no actual stability problems were

observed in the course of exercising the display.

Demo:

OLED-demo.mp4

Receiver

Incremental Tuning:

The

LCD and OLED displays described in preceding paragraphs

show frequency and tuning step, but

not

Receiver Incremental Tuning (RIT). Shortly after the

Hilltopper LCD modification was posted, another ham (NK8O)

created an

enhancement to include

RIT status along with frequency and keyer speed information

in the display

(posted

to HilltopperKit@4sqrp.groups.io).

This

improvement sparked

my awareness of RIT, and prompted me to read the relevant paragraph

in the instruction manual. A crazy thought sprang to mind: Would it be

possible to display both main frequency and RIT information from the

Hilltopper using Ham Radio Deluxe (HRD)?

I imagined inserting a small number of CAT commands

into the Hilltopper’s

microcontroller code, just enough to communicate minimally with HRD. I

did not know which or how many commands

would be needed for a working interface. To probe the

possibilities I set up a test situation using the com0com

utility

to

establish

two virtual COM ports, and to configure them as a

null-modem pair. Next I attached

the

terminal

emulator

program Termite to

one of the ports. Finally, I created a ‘connect’

target entry in HRD, associating the other

COM port of the pair with the Kenwood

TS-440S rig type.

Using this test setup, I attempted to connect HRD in effect to Termite.

In this way it became possible to observe CAT commands from HRD

in Termite’s ‘receive’

area. While attempting to establish a connection, HRD requested

VFO-A and

VFO-B

frequencies (FA and FB commands), general information (IF command) and

the status of frequency and tuning locks (LK command). To be sure those

commands were all that HRD would require to connect and remain

connected, I typed

artificial replies to each command into a text document, then copied

and

pasted them as fast as I could into the terminal emulator’s ‘send’

box. Fortunately HRD is patient—it

does not report failure to connect until multiple command repetitions

have gone

unanswered.

Through trial and error I found that it

was acceptable to join replies end-to-end. In other

words, sending superfluous information or data that HRD had not

specifically requested did not break the connection. Repeating Paste and Enter every few

seconds kept HRD connected indefinitely. In place of probing HRD

in this way

(like a

black box), it might have been more efficient to study the manual. In

any event I concluded that

programming the Hilltopper to supply answers to these commands

would suffice to keep the connection alive.

This conclusion led to a 2-phase coding

plan. In the first phase, frequency information would be transmitted

from the Hilltopper to HRD for display as VFO-A. Then the reverse:

changes to HRD’s VFO-A should produce corresponding frequency changes

in the Hilltopper (bounded by the band edges, of course). Once primary

frequency information was flowing in both directions, the second

phase of coding would address RIT. Although I had no clear idea how to

do this, it seemed that the

Hilltopper’s

RIT function

should somehow link with HRD’s

VFO-B component.

The process of coding and testing was

not without glitches. For example, sometimes the frequency

display would flutter once between the last value and the currently

tuned

value. This was corrected by updating the Hilltopper frequency and LCD

synchronously whenever frequency was adjusted in HRD. Another example

is VFO-B change direction in relation to RIT delta—the direction was

inverted on the first try. (That fix was trivial.) I feel sure that

communication could be streamlined, and possibly HRD’s display

responsiveness could be improved. However, once the interface was

working I felt little urge to improve it.

Electrical interface: The above photos illustrate two

options for connecting the Hilltopper with a computer running Ham Radio

Deluxe. They are conceptually the same, each implementing a USB

(computer port) to serial (Hilltopper) connection. In the left photo

the USB-to-serial cable has an FTDI chip

embedded in its USB-A connector (the computer end). I also tried a

cable that had an embedded PL2303 chipset. That one did not work for either

the

present project or another project

that also needed a bidirectional computer-to-microcontroller

connection.

Note that although very old PCs may have one or more hardware serial

ports (RS-232), these typically use higher voltages and are not suitable

for microcontroller interfacing, or would require converting levels.

Demo: Hilltopper-HRD-CAT.mp4

Project descriptions on this page are intended for entertainment only.

The author makes no claim as to the accuracy or completeness of the

information presented. In no event will the author be liable for any

damages, lost effort, inability to carry out a similar project, or to

reproduce a claimed result, or anything else relating to a decision to

use the information on this page.

>

>

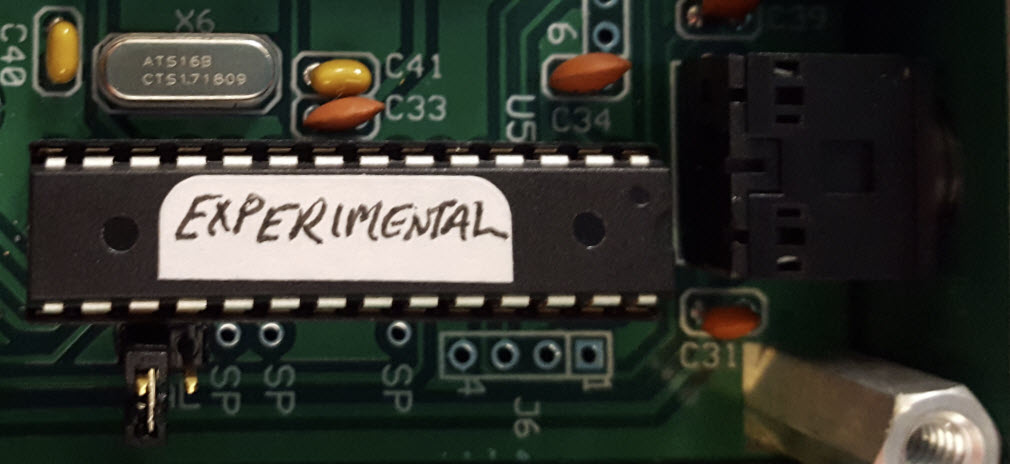

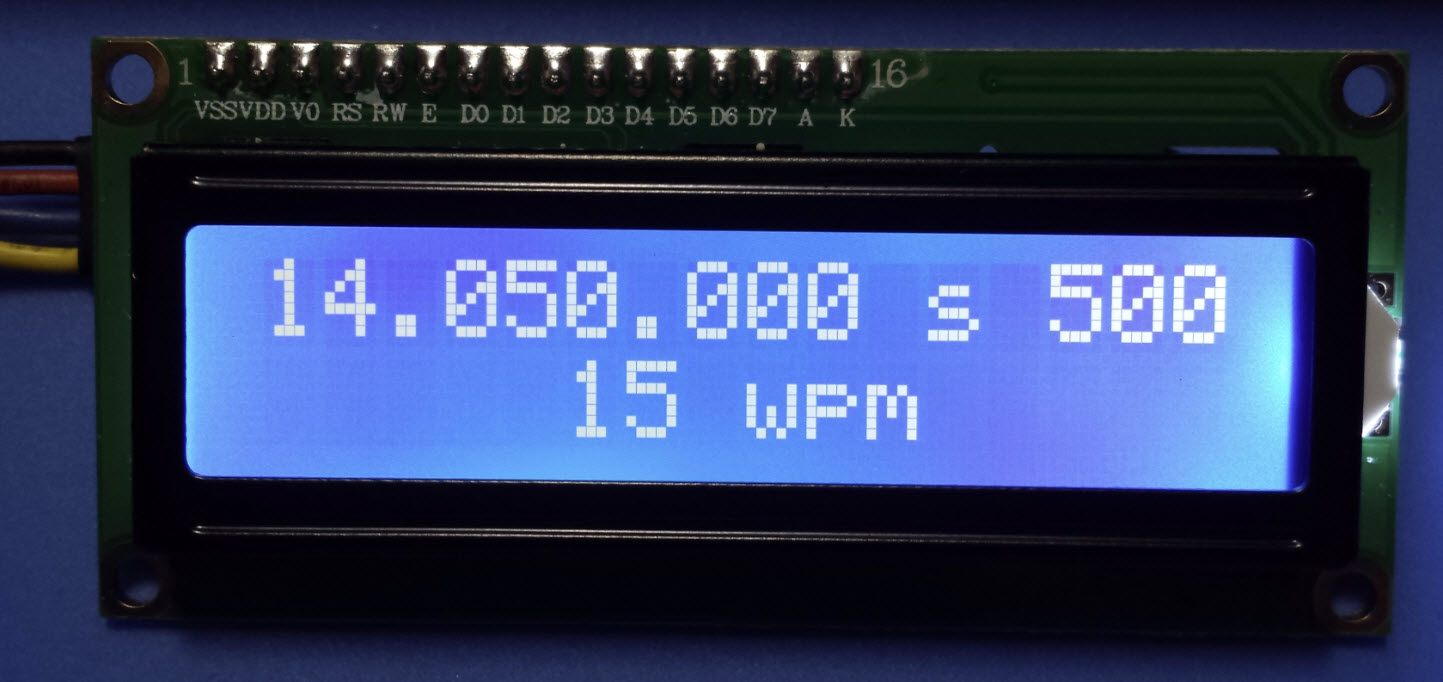

A quick glance at

the schematic detail above reveals that J6 breaks out the i2c

bus.

The main use of i2c is for communicating with the VFO (Si5351 DDS), but

of course a different (though related) application springs to mind. To

that

end I soldered a four-pin header into J6 and made a connecting cable to

use with a 2-line LCD. The first test was to ascertain whether writing

to the LCD would interfere with anything else. It did not!

A quick glance at

the schematic detail above reveals that J6 breaks out the i2c

bus.

The main use of i2c is for communicating with the VFO (Si5351 DDS), but

of course a different (though related) application springs to mind. To

that

end I soldered a four-pin header into J6 and made a connecting cable to

use with a 2-line LCD. The first test was to ascertain whether writing

to the LCD would interfere with anything else. It did not!

Third thought:

Sooner

or later I will let this thing go. The display device pictured on the

left is a 0.96 inch OLED. It is tiny and possibly thin enough to fit in

the Hilltopper enclosure. However, I will not be cutting holes in my

Hilltopper panel—holes

cannot be uncut and such ambitious undertakings always go wrong for me!

Third thought:

Sooner

or later I will let this thing go. The display device pictured on the

left is a 0.96 inch OLED. It is tiny and possibly thin enough to fit in

the Hilltopper enclosure. However, I will not be cutting holes in my

Hilltopper panel—holes

cannot be uncut and such ambitious undertakings always go wrong for me!